The impact and growth of 3D printing have spanned many industries, such as manufacturing, aviation, and health. It’s also become increasingly prevalent for your everyday DIY home hobbyists.

Here we’re going to explore the endless possibilities for 3D printed model trains.

What is 3D Printing?

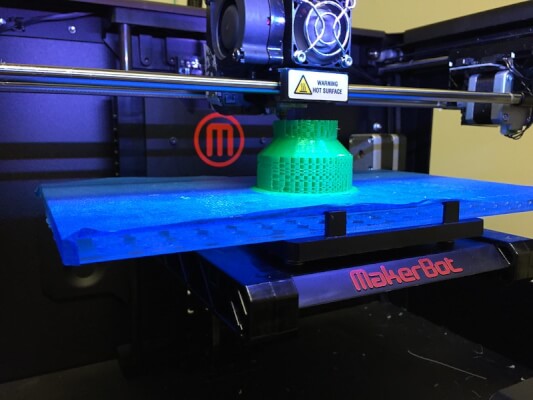

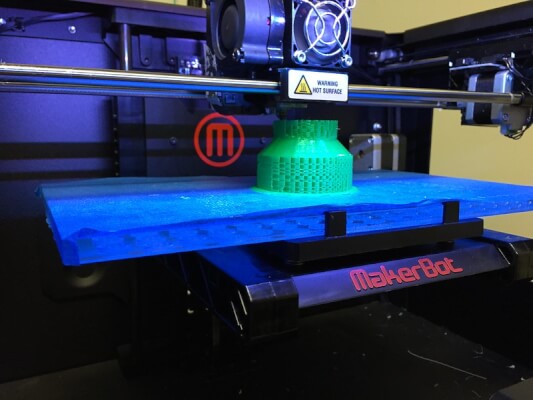

3D printing or additive manufacturing is the process of creating objects with three dimensions from a digital model or file.

3D printed objects are manufactured by adding material to the object, a very thin layer at a time. As 3D printed objects are constructed through an additive process, it is also called additive manufacturing.

3D printing offers a variety of capabilities for the production of products and parts in various materials. Different types of applications are emerging on almost a daily basis.

As this technology is gathering more popularity amongst the industrial, consumer, and maker sectors, the rate of new applications will only continue to increase. It’s already steadily becoming a bigger and bigger thing in the model making community, with people printing everything from full-blown trains to accessories to help detail the layouts.

Are People 3D Printing Model Trains?

Creating virtual objects by using computer software is not a new thing. Automotive manufacturers are creating mass-produced components for a long time. But when it comes to model trains, 3D printing is relatively new.

Model manufacturers like Bachman and Hornby have been using 3D printers for quite some time now. The 3D printing process is also known as rapid prototyping, and this method allows the designers to the outcome of their efforts more realistically than a screen. Even though the traditional method of scratch-building the models is still preferred by many, with the growing affordability of 3D printers, this process is also gaining popularity.

What to Know About 3D Printing Model Trains

There’s actually a bit involved in the 3D printing process. To use a 3D printer to create model trains, we need to know its uses and limitations.

Advantages to 3D printing model trains:

Flexible Design: 3D printing allows print and design to be much more intricate than the traditional scratch-building method. 3D printing lacks the restrictions of the more conventional processes. It also means that if you can find a model online, you can just program it and it will spit out a perfect replica, which is great depending on your skill level.

Rapid Prototyping: Manufacturing parts with a 3D printer can be done within hours. Compared to machining the components by using the traditional process, 3D printing is comparatively less expensive. It is quicker at manufacturing parts, and this speedier rate makes designing and making each piece much more efficient.

Print on Demand: We can make our parts whenever we want. It is most likely we all have different projects that require copies of a component such as doors or windows, structural trim, etc. With the help of a 3D printer, we can make the design and 3d print model train parts overnight.

Tailored Products: We can tailor materials to provide specific properties such as higher strength, water repellency, heat resistance, etc.

Minimizing Waste: Producing parts through a 3D printer requires only the materials for the part itself, which wastes little to none. Whereas, in the traditional process, the wastage is comparatively more significant.

Cost-Effective: If we have a computer that can run the 3D printer’s software, our costs of manufacturing our desired parts would be the cost of the 3D printer, which can be as low as $200, and the cost of the ingredient.

Accessibility: 3D printers are becoming much more accessible, and a wide range of people can use them, unlike the traditional manufacturing process. Also, 3D printing is almost wholly automated, requiring little to nearly no human interaction.

Sustainability: The 3D printing process leaves behind little to no wastage. The environmental benefits extend after considering other factors such as improved fuel efficiency from lightweight 3D parts.

Disadvantages to 3D printing model trains:

Visual Limits: The most significant drawback that we can face using our 3D objects in modeling is that the surface smoothness has its limits. Some of these limits are owed to the additive process.

Limited Materials: Even though 3D printing can manufacture models using a plethora of raw materials, the list is not exhaustive as not all materials can be temperature-controlled enough for 3D printing.

Copyright Issues: As this technology is becoming more and more popular and accessible gradually, the possibility of people creating counterfeit products is also rising. There will almost be no way to tell the difference between the authentic and the counterfeit.

Design Inaccuracies: This problem with 3D printing is directly related to the software, hardware, and process used. Some printers have low tolerances, which result in the end product being different from the initial design.

How Long Does 3D printing trains usually Take?

It really depends on the machine. Generally, it takes 2.5 hours to print something really small, and around 6 hours for anything consisting of a length of 10cm or above. The big benefit of 3d printing is that you don’t have to be present the whole time.

After the first few layers have been added, the printer doesn’t require any more human interactions.

It is advisable to use abrasive to remove any evidence of printing in the post-processing to give it a more realistic look. You can do this by just using a scalpel to scrape off some of the mould lines, or even hitting it with some gentle sandpaper depending on how intricate your model is.

What is the Best Material to Use?

There are many types of filaments available that are used for 3D printing. Here we are going to talk about the most common ones used.

Poly Lactic Acid (PLA): PLA is a biodegradable polyester derived from sugar cane or corn starch. This is an excellent material for beginners to start with. It is ideal for creating small and simple items. When PLA is heated for printing, a sweet smell can be found. As it is biodegradable, we can dispose of it in a compost bin. It cools quickly, so there are little to no chances of model warping. However, we have to consider that it has a low melting point, so using high heat to reform this material is advised against.

Acrylonitrile Butadiene Styrene (ABS): It is a petroleum-based plastic that will be familiar to modelers and children. This is what Lego bricks are made of. It requires a heated print bed, and higher nozzle temperatures of around 240 degrees Celsius are essential. As it takes longer to cool down, models are susceptible to warping.

Due to its simple usage and accessibility and the reliability of its end products, the 3D printer is gaining popularity very quickly. Its pretty easy to see why too. The ability to print anything you can get a model for, or even making your own custom work for your layouts is an incredibly enticing idea.

3D printing everything from model trains to people to buildings for a train layout is already becoming the norm for a lot of modellers, and its only growing in popularity.

If you were on the fence about 3D printing your railway models, we hope this article has helped you make your final decision.

Peter has been building model trains for longer than he can remember. An avid fan of HO and O scale this blog is a creative outlet to allow him to dive further into other scales and aspects of the model train community and hobby.

Hello,

Do you have contact info? The contact form does not seem to work.

Take care.

Joe